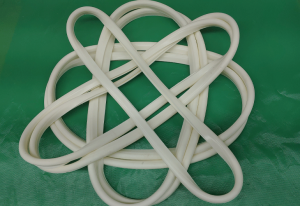

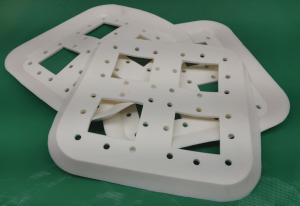

Molded Parts - Types Of Molding

Polyonics Rubber Company can mold your custom molded product using

- Compression Molding

- Transfer Molding

- Prototype Molding

- Rubber to Metal Bonding

We can use your existing mold or help in the design and procurement of new tooling, including prototype molds. Our experienced technical staff can help you get the tooling you need to produce the part that will meet your specifications at the lowest cost.

Our equipment allows us the flexibility for prototype, short run, or high volume runs and our press line can accommodate nearly all compression and transfer molds.

Compound Design & Mixing

We will formulate and mix a rubber compound to meet ASTM, Military, or customer specifications. Polymers we routinely use are:

- Silicone

- Neoprene

- SBR

- EPDM

- Nitrile

- Polyisoprene

- Fluorosilicone

- Urethane

- Butyl

- Hypalon

- Polysulfide

- Buna-N

- Viton

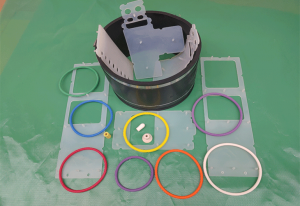

Finishing

We employ various de-flashing techniques to provide you with a complete, finished product. Methods used include:

- Tumbling or Cryogenic De-Flashing

- Grinding

- Die Cutting

- Hand Trimming

- Machine Buffing

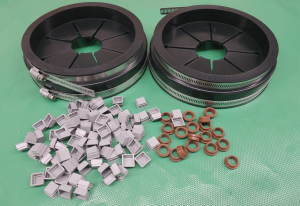

Rubber to Metal Bonding

Polyonics Rubber Company specializes in rubber to metal bonding, using a wide array of rubber compounds and adhesives that can bond to various metals. In some cases, it is necessary or economical to re-use the metal inserts. We can remove the old rubber from the inserts and apply a fresh rubber compound to them to save you money.

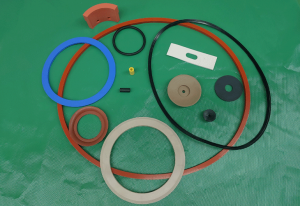

List of products

- Seal Rings

- Vacuum Cups

- Bellows

- Handle Grips

- Door Seals

- Grommets

- Drum Seals

- Sander Pads

- Reservoirs

- Bladders

- Rollers

- Plugs

- Pump Blocks

- Ax Handle Grips

- Valve Seals

- Suction Cups

- Petroleum Seal Off Plugs

- Hammer/Mallet Heads

- Golf Putter Heads

- Bushings

- Rubber to Metal Bonding